OUR FACTORY

Sandnes Garn today holds the position as the largest producer of hand knitting yarn in Northern Europe, one of the world’s most up-to-date spinning mills – in one of the oldest factories in Norway still running.

The factory in the center of Sandnes burned to the ground in 1978 and was rebuilt in a valley outside of town. We contribute in a big way – to the joy of knitting in general, as no less than 15 million balls of yarn leave the premises every year.

By the time the balls of Peer Gynt and Fritidsgarn are picked up in a yarn shop in Oslo, Uppsala, Århus, Helsinki, Reykjavik, New York, Montreal or Torshavn, they have already made quite a journey. These yarn types originate from the wool of Norwegian sheep, which is then transported to the factory for washing, carding, spinning, twirling, dyeing and balling. For all who are part of the process, be it animal or people, strict standards of welfare and general happiness apply.

Here we show the whole process from washing the wool to finished skeins in stock.

Thanks to the sheep!

Once the wool arrives from our supplier, it is sent directly through the washing machine.

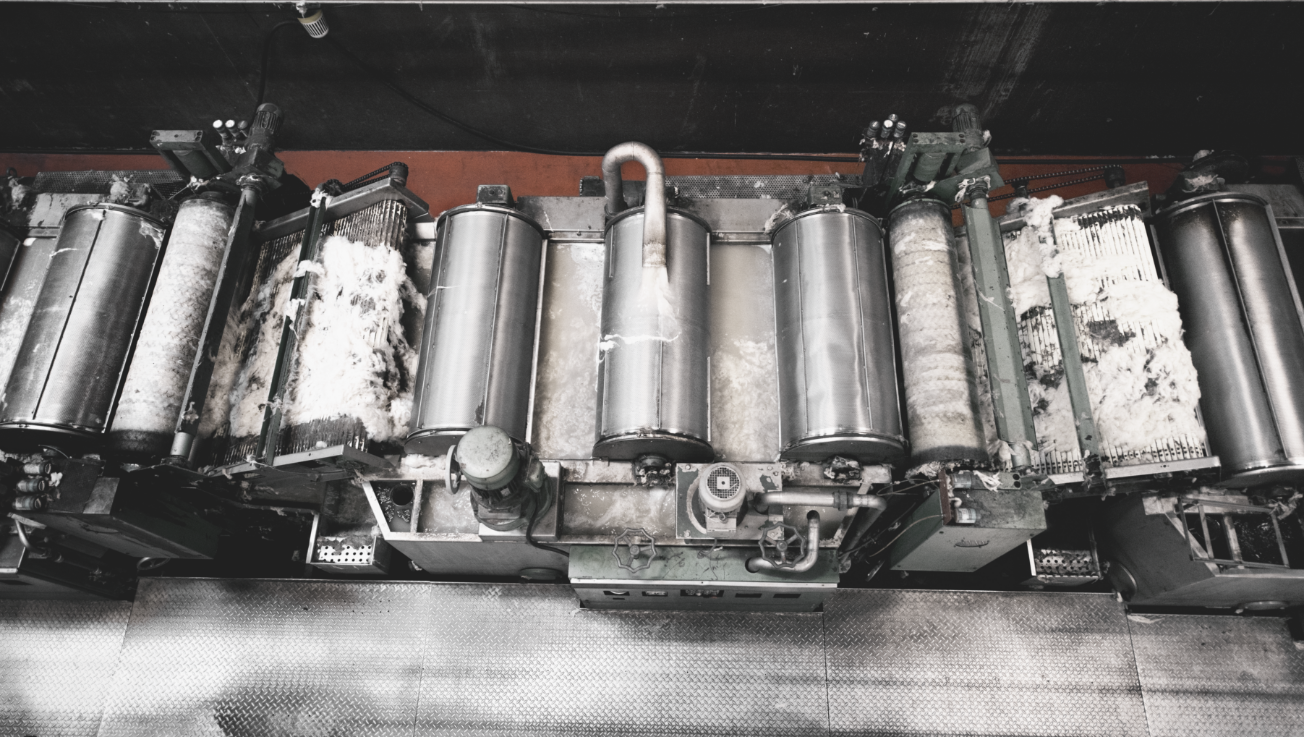

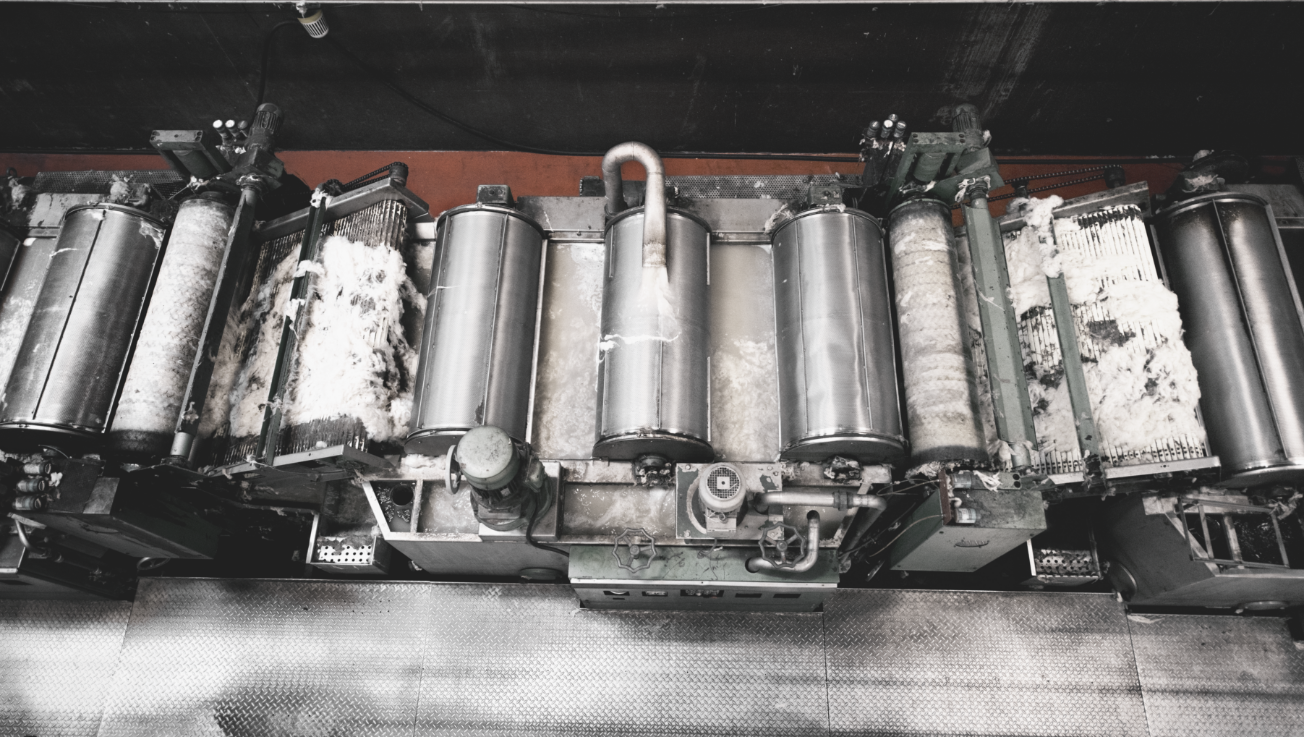

After being washed, the clean wool goes on to be carded before its ready for spinning.

Prepared tops are supplied as raw material in production of worsted yarn. Tops are washed and combed wool. For larger dye lots, tops are dyed before spinning.

Prepared tops ready for spinning.

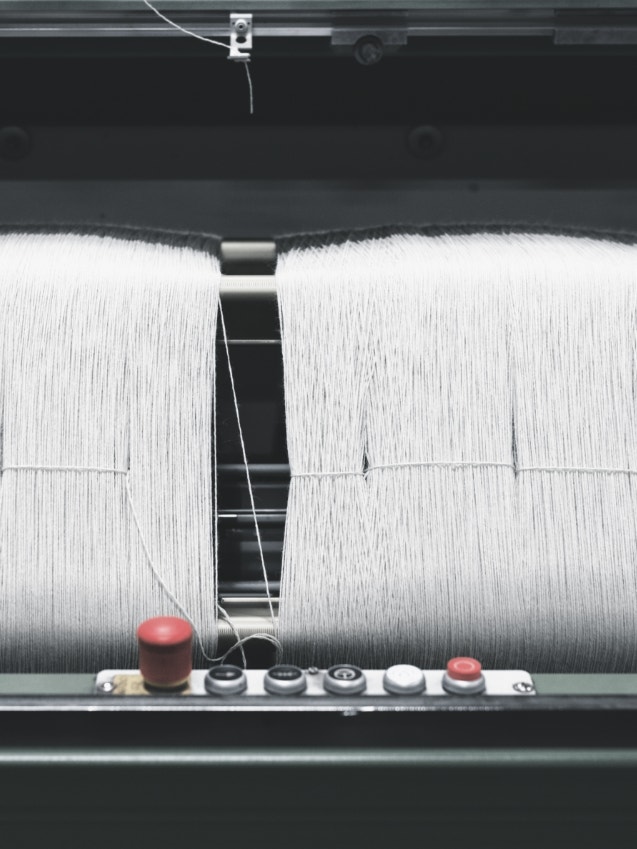

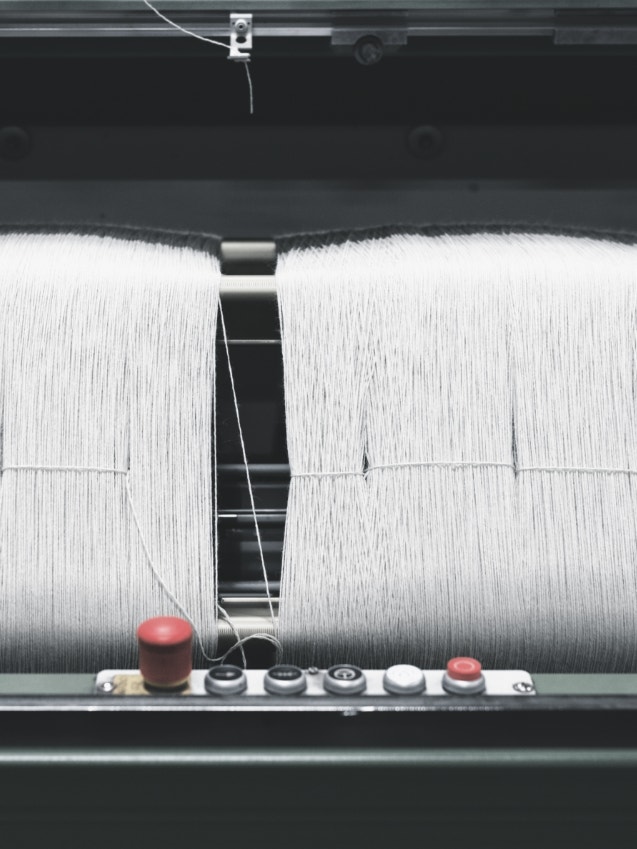

The worsted yarn being spun.

The yarn transferred from cones to skeins.

In our dye kitchen colors and chemicals are mixed. Only ecofriendly products, certified by strict Norwegian and international regulations, are used. Each dye lot contains 200 kg yarn.

After the dyeing process, excess water is squeezed out between rollers before a robot picks up the skeins for transport to the air dryer.

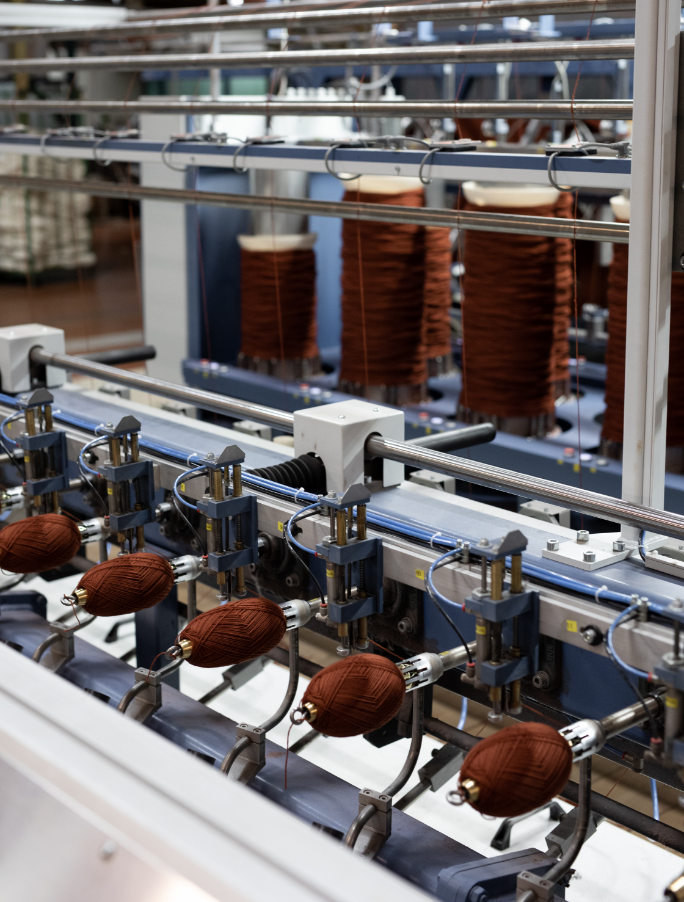

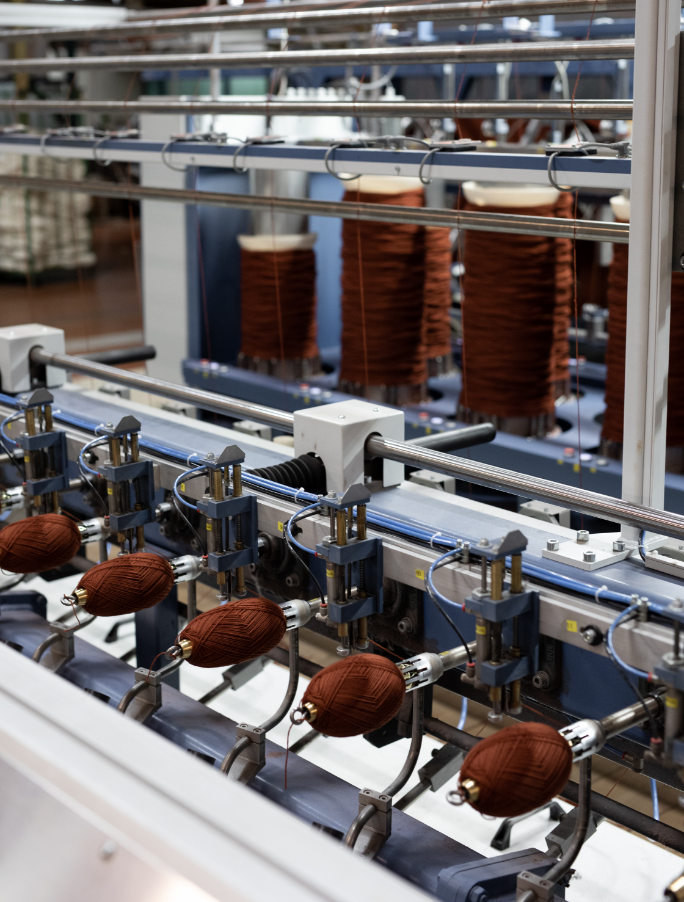

From skeins the yarn is fed into our 4 automatic balling machines which ball, put on banderoles and pack the balls into bags.

Sandnes Garn is also a distribution center with great capacity and flexibility. We can handle orders individually and ship directly to yarn shops as well as wholesalers.